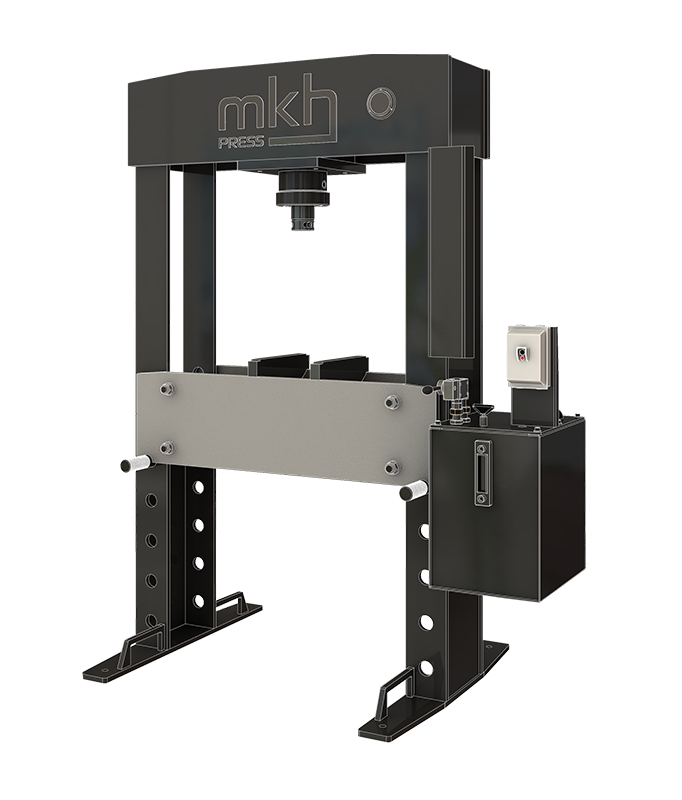

Workshop presses

Hydraulic MKH presses are suitable for a wide range of applications and industries. The reliability and long service life of the hydraulic MKH presses save costs. They are easy to use and do not require separate training. The products meet the safety requirements in accordance with ISO 16092-1:2017 and ISO 16092-3:2017 standards.

HAND-OPERATED WORKSHOP PRESSES

Easy-to-use, hand-operated hydraulic presses are manufactured for efficient work. The press is operated with a hand pump and adapts well to varying pressing needs and workpieces.

With the two-speed hand pump, the operator can choose between high speed/low force or low speed/high force mode depending on the requirements of the job at hand.

Hand-operated presses are is the best and most cost-effective solution when the use is not continuous. Standard hand operated HPE models have a pressing force of 30 – 60 tons / 300 – 600 kN.

MOTORISED WORKSHOP PRESSES

Hydraulic presses powered by electric motors are a good option when the use and the required pressing force is greater. Electric hydraulic presses allow for faster turnaround times and greater force.

The standard motorized models have a pressing force of 30 – 300 tons / 300 – 3000 kN, of which the MPDS models with a pressing force of 150 – 300 tons / 1500 – 3000 kN operate with fast movement. For smaller MPD models of less than 150 tons / 1500 kN, fast movement is available as an accessory. Fast movement allows fast approach to the workpiece.

HYDRAULIC PRESSES TAILOR-MADE ACCORDING TO YOUR NEEDS

Tailor-made hydraulic presses are designed and manufactured to meet the customers’ needs. They can be, for example, various frame solutions or presses suitable for demanding workpieces. Tailor-made hydraulic presses can be of both small and large size models . Pressing forces can reach up to 2000 tons / 20000 kN.

The presses are also available with a servo-hydraulic control system, developed by MKH, for the most demanding applications. The servo-hydraulic system enables fully automated operation and complete control of the pressing parameters. Tailor-made presses can be equipped with faster movement speeds (> 10 mm/s) and combined with material feeders or robots.

MOTORIZED SERVO HYDRAULIC MPD NC WORKSHOP PRESSES

Fully programmable for:

- pressing force

- pressing speed

- stroke length

NC presses can be easily programmed with automatic work cycles and can be equipped with, for example, material feeding robot for unmanned production.

The NC control system also enables real-time monitoring of pressing parameters and the ability to store the pressing events on an external memory. This enables the press to be used, for example, as a test device.

Standard models of the MPD NC presses:

MPD 40 NC, MPD 100 NC, MPD 200 NC